Mixing and Agitation

Propeller

This type of propeller is the most common type in mixing industry. Because the design has its roots in the marine propulsion industry, it is the most effective axial pumper at higher mixing speeds. It is most commonly used with direct drive mixers operating 300-1000RPM.

3HE High Efficiency

The modern design of this impeller provides excellent pumping ability with a strong axial flow. While useful in most applications, this design excels in thinner fluids that are susceptible to settling and provides the MOST pumping per unit of torque. This impeller is available as a welded or bolted assembly. The 3HEimpeller can be fabricated to fit ANY shaft diameter and comes standard in 316 Stainless Steel, but 304 Stainless Steel.

4 Blade Turbine

This is the workhorse of the mixing industry. The simple design of this impeller provides a combination of both radial and axial flow, generates high shear levels, and provides excellent mixing ability while providing easy cleanup. Because of the simple design, it is also very cost effective in large applications and high viscosity applications.

Twin Blade Paddle

This is Wemix Designed Twin Blade Impeller which is normally for low viscosity product. Widely used in Waste Water Treatment for Flocculation, Ph Adjustment and Even Polymer Mixing.

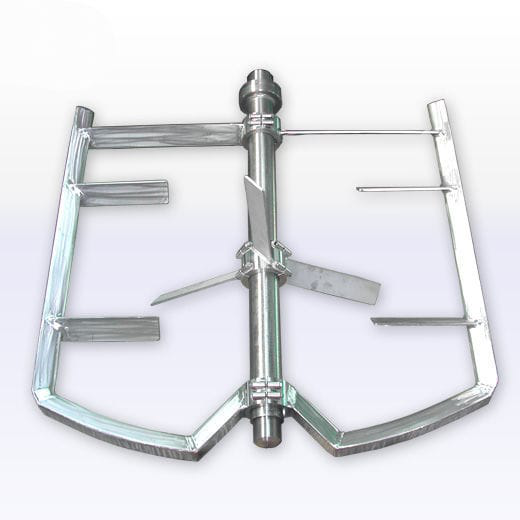

Impeller with Stabilizer Ring

This is Wemix Designed Impeller with Stabilizer Ring. The Outer Ring Act as a Stabilizer to Reduce the Vibration and Stabilize The Impeller with Mixing. This is normally used for High Speed Mixing which from 1500 Rpm Above.

Folding Impeller

Folding impellers are most commonly used in mixing applications where access to the vessel is limited, such as Drums or IBC Tank. WEMIX folding impeller design is essentially from two blades to four blades, pitch blade turbine impeller design, where the blades fold down against the shaft when not in use. The folding design allows the impeller and shaft to be inserted and retracted through the opening of the drum or IBC tank.

Anchor Blade

Also can consider as a Close Clearance Impeller. The Diameter of the this impeller typically is 90 – 95% of the Internal diameter of the vessel. The Shear near the vessel wall reduces the build-up of stagnant material and promotes Heat Transfer. The Anchor Impeller is a radial flow Impeller.

Anchor Blade

Also can consider as a Close Clearance Impeller. The Diameter of the this impeller typically is 70 – 80% of the Internal diameter of the vessel. The Shear near the vessel wall reduces the build-up of stagnant material and promotes Heat Transfer. Helical Impeller also provides discharge of material by producing strong top to bottom motion.